We import our coffees within a hermetically (airtight) sealed food grade bag, encouraging the bean to remain stable during transport and storage. Insects and moisture are met with an impassable barrier, and are made with confidence and quality.

The beans having transitioned from green to brown in colour have lost weight but increased in size. Having exited the roasting drum, it is imperative that the coffee beans are rapidly brought down to room temperature as quickly as possible.

Long metal arm carefully agitate the coffee in whirlpool fashion while large fans extract the air above the cooling tray through the beans and out of the roaster. We have found this method of dragging cooler air past the beans surface area brings the temperature down quickly and gently.

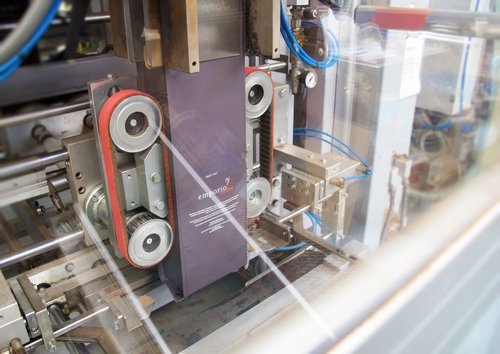

Our Emporio Coffee bag transitions from a reel to a full bag by way of a process that applies the degassing valve (2 way valve) and prints on the best before and batch number. Whilst the bag is finished being sealed along its edge, the coffee is dropped into bag, inert gas like Nitrogen displaces the ambient air and the bag is sealed. This process provides a long shelf life as well.

.

Our final bag is 120 microns of aluminium and food grade plastic geared to providing the best environment for the beans to be transported before finally meeting our customers. Our process is HACCP certified and is the very best in packaging techniques aimed at quality through the entire process.

If the laminate wasn't enough, six one kilogram bags refilled within the carton and batch ensuring no matter how you receive your coffee, it is at its absolute best.